Platinum Group Metal Demand Will Increasingly Outstrip PGM Supply – by Dr. David Davis

Please find our latest research report on the impact of South Africa’s energy crisis on Platinum Group Metals mine supply.

South Africa has faced ongoing periods of widespread rolling blackouts (load shedding) for many years and the future looks extremely bleak for Eskom, the national electricity utility provider.

In the worst-case scenario, the effect of this “energy crisis” is likely to be overwhelming and will undoubtedly have a crippling effect on South Africa’s economy, PGM mining activities and therefore the global supply of Platinum in particular, given that South Africa produces 72%, 36% and 82% of the world’s Platinum, Palladium and Rhodium respectively.

The Critical Concerns Are:

- Disruptions to mining operations caused by higher electricity load shedding stages and more frequent load shedding will have an increasingly more severe impact on PGM production over the coming years.

- Load shedding at Stage 6 and above would mean that the miners would not go underground and operations would cease causing major PGM supply disruption.

- The impact of a diminishing and intermittent electricity supply can be attributed to a worsening cauldron of political ideology, political interference, state capture, mismanagement, lack of skills, poor maintenance, unscheduled breakdowns, crime and corruption.

- Mismanagement, cost constraints, the lack of skills and unscheduled breakdowns of the ageing coal-fired plants many of which are to be decommissioned.

- New-builds of electricity capacity are likely to be late, exacerbating the energy crisis.

- Considerable capital constraints to the energy recovery plan and lengthy delays, in part caused by corruption, will continue to hamper the procurement process.

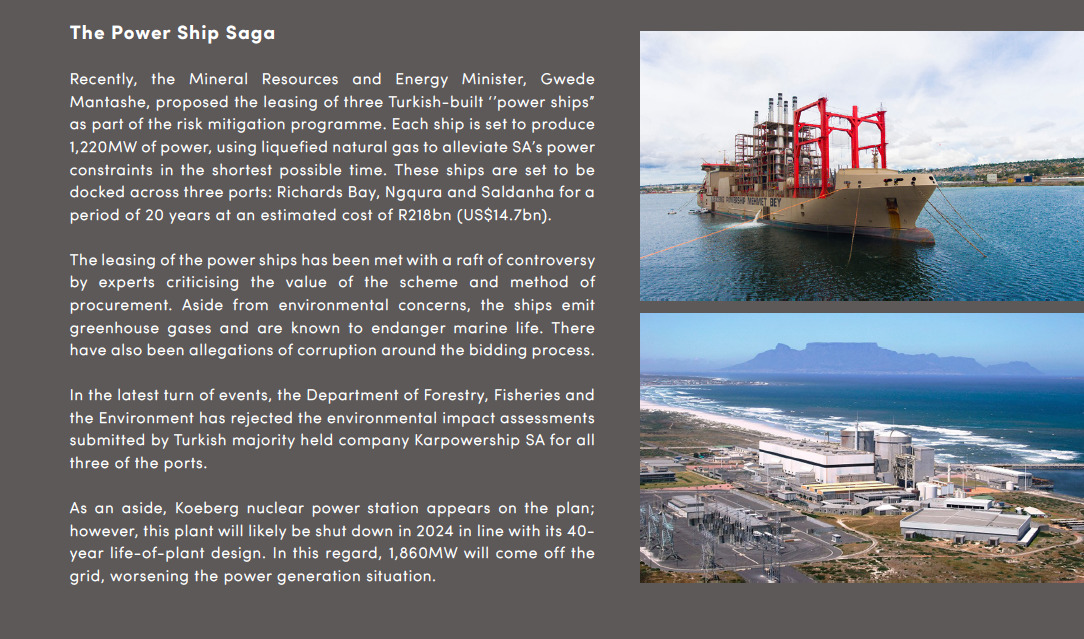

- Plans for emergency power ships are likely to be scuppered due to the disastrous ecological and environmental impact.

- industrial action, political upheaval, increasing costs and a significant reduction in capital expenditure. The PGM mining industry has been starved of expansion and ore reserve replacement capital for a number of years.

- In summary, the PGM supply from South Africa will almost certainly start to decline within the next 2 to 3 years when higher levels and frequency of load shedding persist; at the same time that industrial and investor demand for Platinum is forecast to dramatically increase. The future demand for PGMs is all about climate change and the drive for net zero emissions by 2050.

- The progressive tightening of environmental regulations and technology innovation surrounding the production of green hydrogen has led to and will continue to lead to, an increase in PGM demand. Coupled with the supply-side restraints, in part, caused by the energy crisis, this will almost certainly cause a major price resolution in Platinum.

INTRODUCTION

This review provides an insight into the “potential” impact of a diminishing and intermittent electricity supply from South Africa’s power utility (Eskom) on the future of South African Platinum Group Metal (PGM) mine supply.

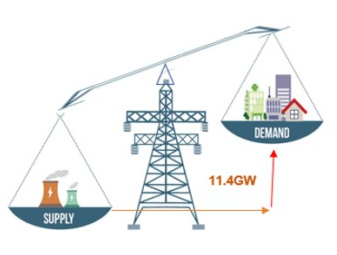

Since 2007, South Africa has faced ongoing periods of widespread rolling blackouts (load shedding) as supply continues to fall behind demand, threatening to destabilise the national grid. The situation, some 14 years later, has reached “crisis level”.

In the worst-case scenario, the effect of this “energy crisis” is likely to be “overwhelming” and will undoubtedly have a “crippling” effect on South Africa’s economy. Manufacturing, agricultural, industrial, mining, transport and domestic users will not go untouched if the electricity supply shortage is not urgently addressed and reversed by replacement and additional new capacity from coal, gas, wind, storage and solar.

The government and Eskom do not have a good record of completing projects on time and therefore there is a high probability that the new-build of electricity capacity will be late, thereby exacerbating the energy crisis.

The objective of this review is to provide evidence and timing to support this scenario. The outcome will determine the degree and level of load shedding and its impact on PGM supply from South Africa.

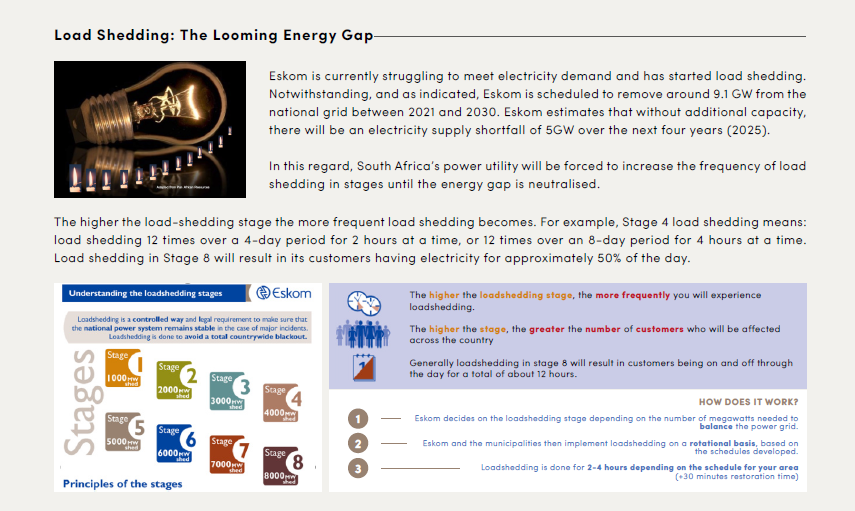

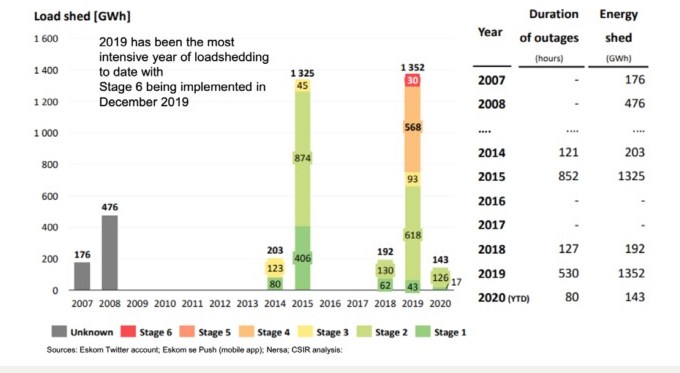

It is important to recognise that load shedding is a controlled way and legal requirement to make sure that the national grid remains stable in the case of major incidents. Load shedding is done to avoid a total countrywide blackout. There are 8 stages of load shedding. Eskom decides on the load shedding stage depending on the number of megawatts (MW) required to be saved to balance the grid.

For the investor in precious metals, the degree and level of load shedding and the impact on PGM supply from South Africa will likely support the price of PGMs. The PGM industry can cope with load shedding Stages 1, 2, 3 and 4, albeit at Stage 4, and at higher frequencies, throughput may have to be adjusted downwards. At Stage 6 and above operations would cease.

I am of the view that it is “imperative” for investors to gain an understanding of those factors that have led to the demise of Eskom, which in turn, has led to a decline in electricity supply (negative electricity supply gap) and will, in my view, continue to do so. Much of this review describes the demise of Eskom. In this regard, I have used a number of graphics to illustrate the conversation.

My research indicates that it is most likely that the energy gap will widen significantly over the next 5 years, caused mainly by a low energy availability factor (EAF) of the coal- fired plants, a “slippage” in the new build programme (3 to 4 years) and capital constraints. This, together with political interference and vacillation with respect to the recovery plan, will likely cause a rise in PGM supply losses. In this regard, the PGM supply from South Africa will probably start to decline within the next 2 to 3 years when higher levels and frequency of load shedding persist, including Stage 6 and above ceteris paribus. (Noting, Stage 6 and higher would cause mine operations to cease).

Setting The PGM Scene

Demand for PGMs is all about climate change and the drive for net zero emissions by 2050.

In this regard, the auto industry has introduced new types of drivetrains for vehicles, with a move from ICE to BEVs, HEVs and FCEVs to meet new emission standards. These new standards mean higher autocatalyst PGM loadings. The new emission standards also mean accelerated demand for FCEVs that contain platinum (mainly heavy-duty vehicles).Furthermore, PEMs’ electrolysers, which also contain platinum, are currently seen as the most cost-efficient way to produce green hydrogen from renewable power as they are able to withstand the intermittency of renewable generation.

The progressive tightening of environmental regulations and technology innovation surrounding the production of green hydrogen has led to an increase in PGM demand. My

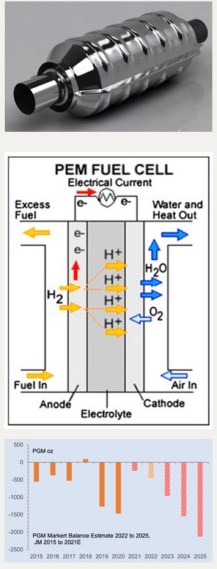

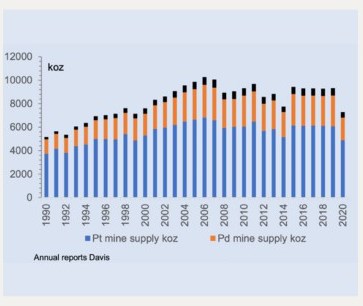

calculations imply that global PGM demand will likely grow at a rate of around 3.5% CAGR (2027). In this regard, my estimates are not too dissimilar from GlobalData’s estimates.Global PGM mine supply will most likely remain roughly constant with an average PGM of c.13moz, with a recognisable downward trend starting around 2031. Under these circumstances, I am of the view that PGM demand will increasingly outstrip PGM supply.

This scenario is already playing out. The market balance for palladium has been in deficit for at least nine years, rhodium has been in deficit over the past two years (JM). In both cases, the supply imbalance has been the main driver of the sky-rocketing price of these metals. Platinum has a positive outlook due mainly to substitution in petrol autocatalysts and an increase in catalyst loadings together with a global decline in platinum supply.

I expect platinum to move into deficit in 2022.

South African PGM Supply Risk

The continuity of South African PGM supply is not secure. The South African PGM mining industry has faced numerous challenges in the past caused mainly by the combined effects of electricity shortages (load shedding), prolonged industrial action, political upheaval, increasing costs and a significant reduction in capital expenditure. The PGM mining industry has been starved of expansion and ore reserve replacement capital for a number of years.

South Africa has experienced 14 years (from 2007) of intermittent load shedding stages between 2 and 6. Currently, Eskom is implementing load shedding. Furthermore, Eskom has recently warned that it expects load shedding (Stage 4) to increase towards the end of 2021, as it is facing a 5GW shortfall, which is expected to continue for at least another 5 years. The higher the load shedding stage, the more frequent load shedding becomes. In this regard, the impact on PGM production will likely

become more severe.

At this stage of the conversation, it is important to put into perspective the potential impact of this looming “energy crisis” on some of South Africa’s

strategic mining exports such as PGMs, manganese, chrome and coal.

- South Africa produces 72%, 36%, 82%, 81% and 87% of platinum, palladium, rhodium, ruthenium and iridium respectively (JM), (SFA Oxford).

- South Africa is the number one global exporter of manganese, producing 5.2mt in 2020, some 37% more than the runner-up, Australia, at 3.3mt. China was the fifth largest producer of manganese in 2020, recording output of 1.3mt. It should be noted, however, that a number of manganese mines have their own generators which supply them with electricity.

- South Africa produced 16mt of chromium in 2020, beating the rest of the world’s chromium producers by a wide margin (58%): Kazakhstan came in at number two,

producing 6.7mt of chromium. - Based on the latest available data, South Africa’s coal exports increased in 2020. In a recent report, shipbroker Banchero Costa said that South Africa is the fourth largest exporter of coal in the world, after Australia, Indonesia and Russia.

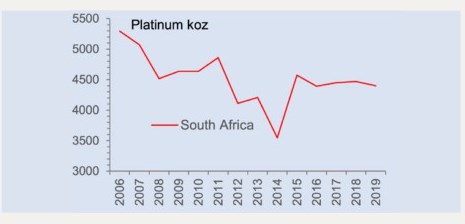

I note that global mine supply of platinum has grown by c.1.7% CAGR between 1990 and 2020. In 2019, global mine supply was some 6.1moz (JM). Global platinum mine supply depends heavily on the South African PGM mining industry, which supplies about 72% of global platinum. Russia, North America and Zimbabwe supply around 12%, 6% and 7% respectively ( JM 2019). Global platinum mine supply between 2006 and 2019 declined by c.-1.0% CAGR. South African platinum mine supply declined by c.-1.4% CAGR. The gradual decline in the supply of platinum is mainly attributed to the historical evolution of the mining mix ratio of the PGM reefs in South Africa and to the lack of capital investment.

It is clear from the above list of strategic exports that an “additional” decline in PGM supply from South Africa, due to a continuous decline in power supply, will likely become more sensitive as PGMs are inextricably linked to climate change. Furthermore, the PGM market balance will inevitably move into a continuous and declining deficit, which will put upward pressure on the price, in particular the price of platinum.

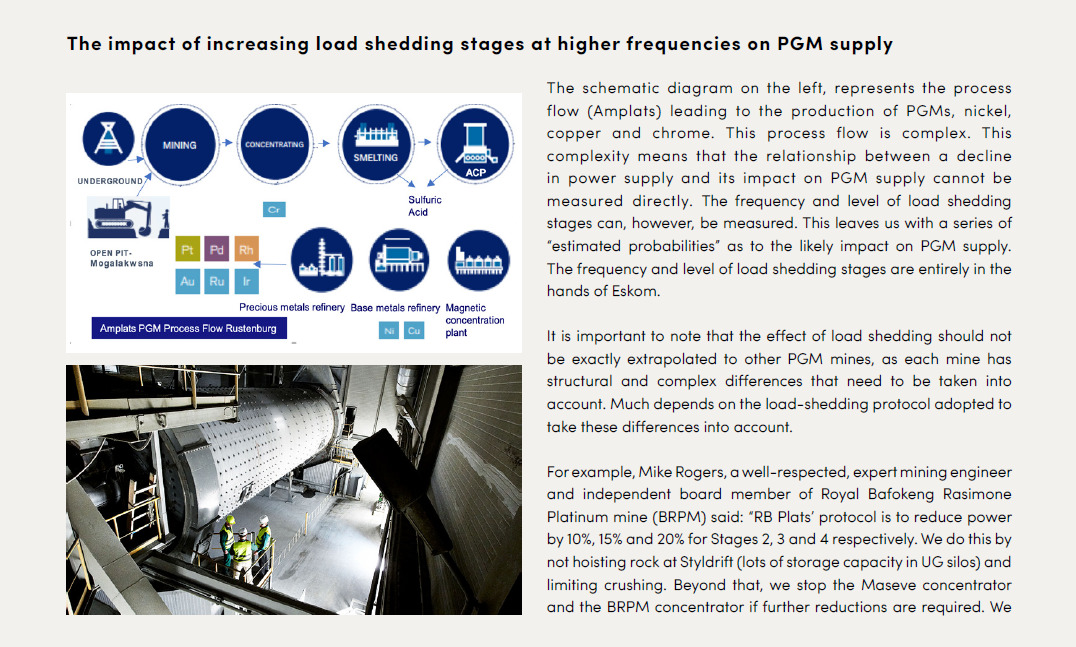

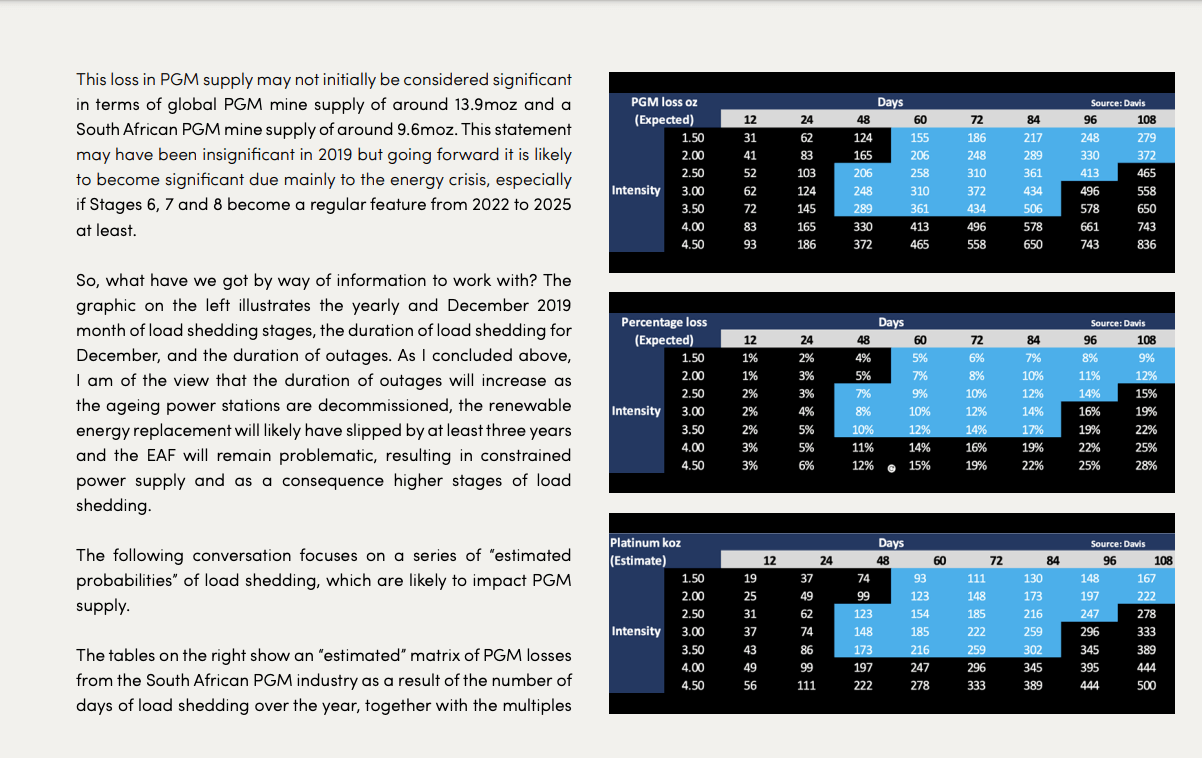

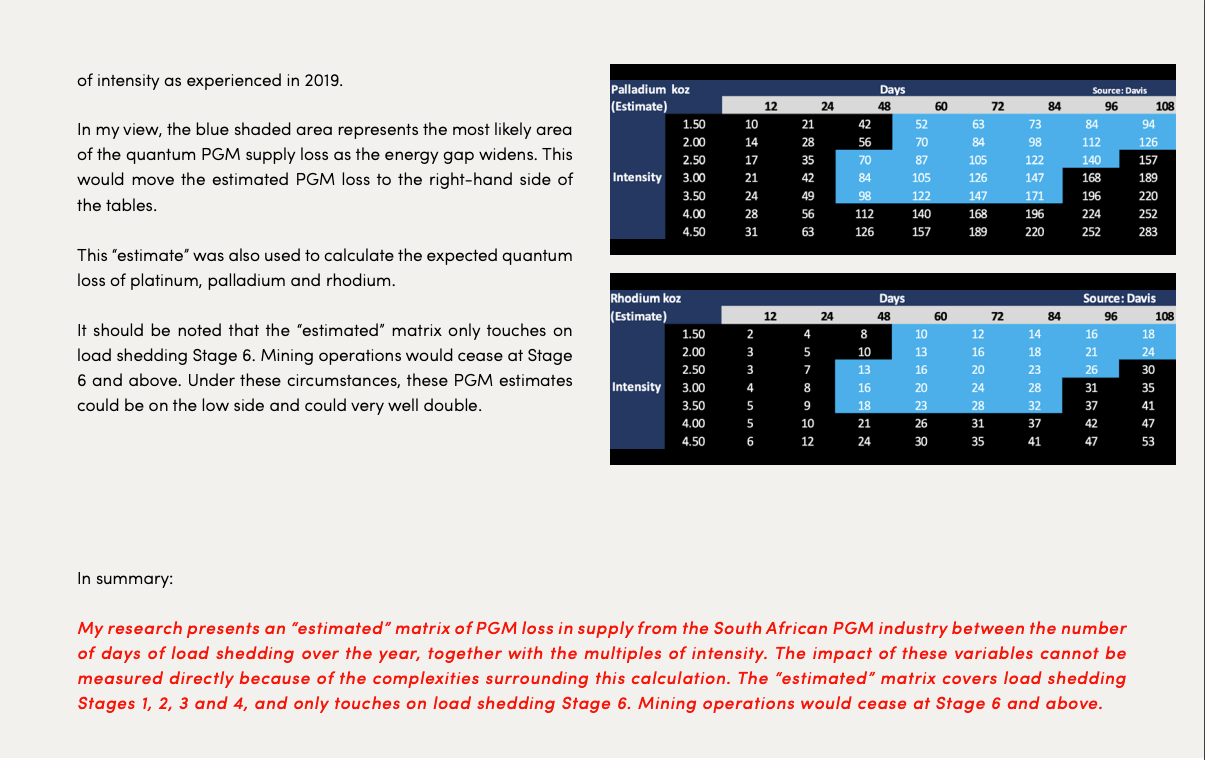

It is important to note that the relationship between a decline in power supply and its impact on PGM supply cannot be measured directly because of the complexities surrounding this calculation. The frequency and level of load shedding stages can, however, be measured. This leaves us with a series of probabilities as to the likely impact on PGM supply. The frequency and level of load shedding stages are entirely in the hands of Eskom.

This conversation therefore focuses on Eskom and its ability to achieve its new build plan.

Setting The Energy Crisis Scene

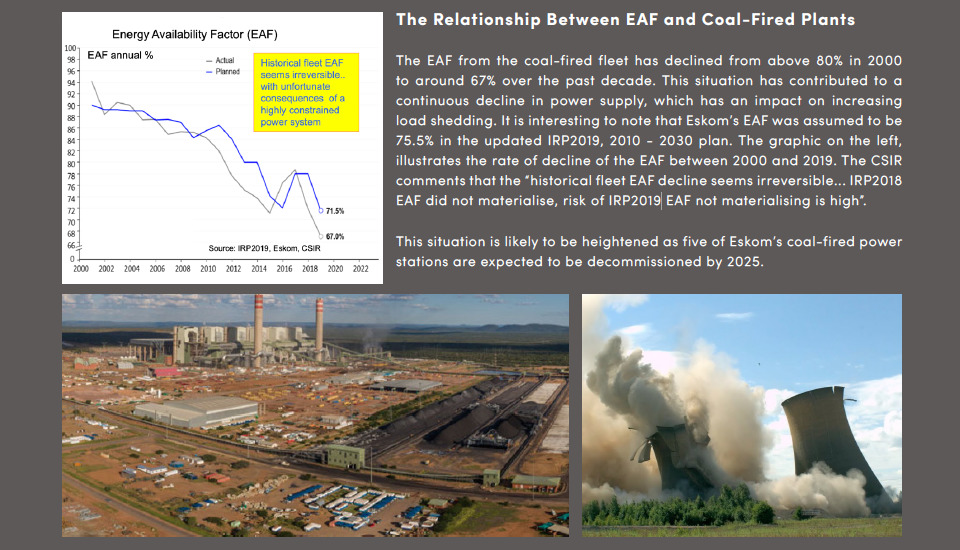

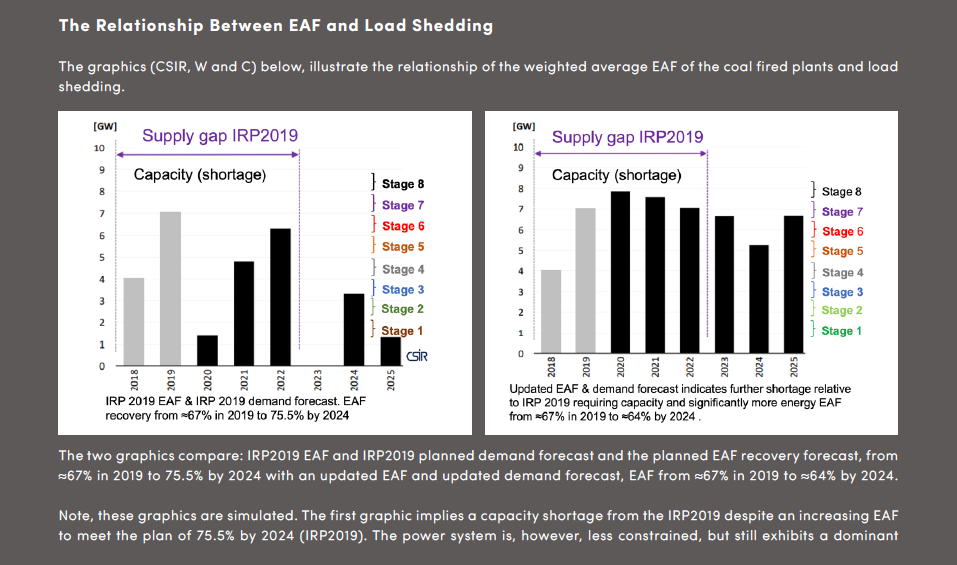

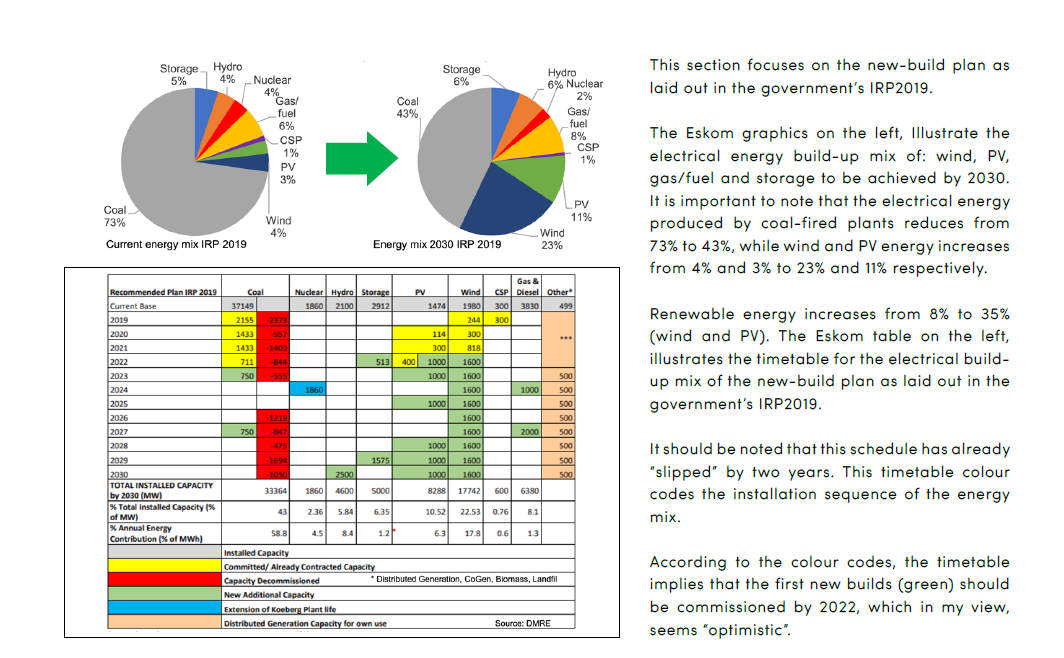

This section sets the scene as the energy crisis unfolds. The government has set out a plan (IRP2019) designed to neutralise the electricity supply gap by reducing the existing dependence on fossil fuels to a mix of renewable energy sources. In this regard, apart from the availability of capital, there are two pivotal key factors that will drive the successful accomplishment of this exercise. These are: the energy availability factor (EAF) of the coal-fired plants must increase from 67% to 75.5% and above by 2024, and the new plan must be executed between 2021 and 2030. If one or both of these pivotal key factors are not achieved the plan will fail, and Eskom will be forced to increase the frequency of load shedding until the energy gap is neutralised.

An Integrated Resource Plan (IRP) for electricity is a rational, mechanistic, techno-economic planning process that determines the optimal mix of generation technologies and capacities, with the least cost to the economy, necessary to meet the projected demand for electricity in the years ahead, with defined reliability and security of supply (Eskom).

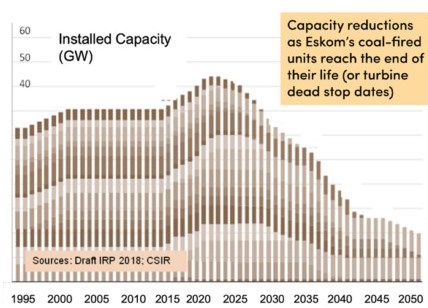

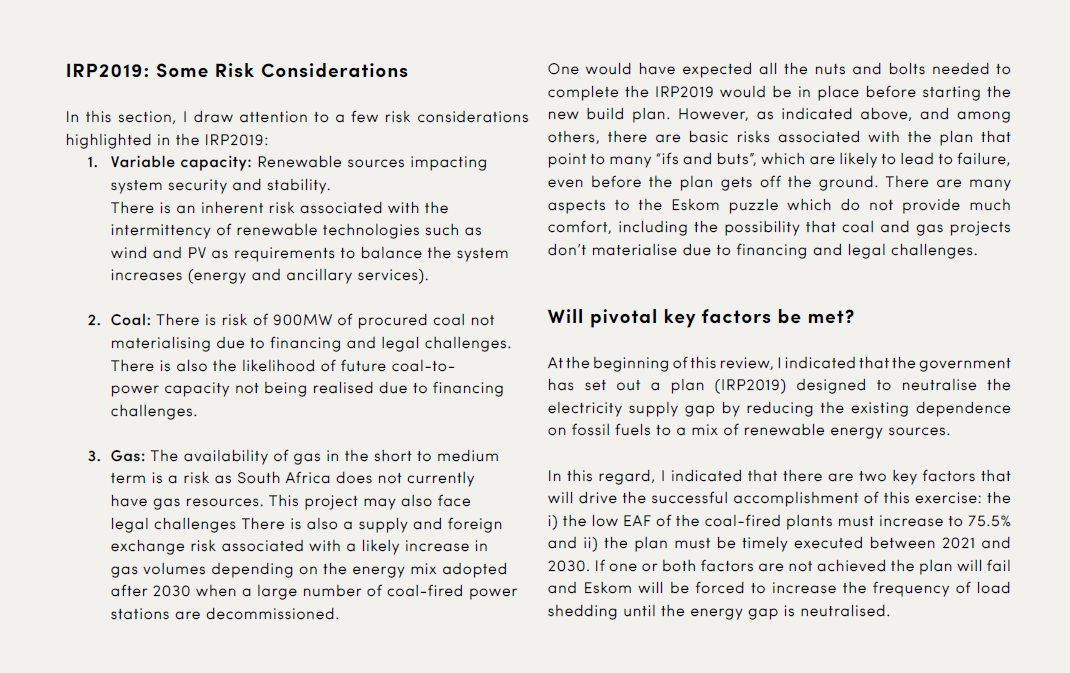

There is, however, an overarching factor which will have an impact on the execution of this plan; many of Eskom’s coal-fired plants are old and reaching their end of life. In this regard, five out of fifteen coal-fired power stations are expected to be decommissioned by 2025.

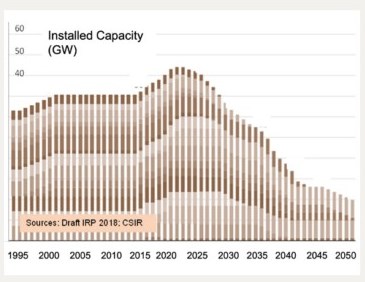

The decommissioning of these power stations will remove around -3.8GW from the grid between 2020 and 2025 and -9.1GW between 2020 and 2030.The decline between 2020 and 2030, and on to 2050 is relatively steep.

This means that it is imperative to replace the loss in capacity timeously, as per the new-build plan. Any slippage, as indicated above, will mean prolonged periods of load shedding.

Energy expert Ted Blom has indicated (MyBroadband) that “he would not be surprised if between now and the end of winter 2021, we will experience Stage 6 load shedding, pretty much for certain, and even Stage 8 or above that is a possibility’’.

In a surprise move, South Africa’s President Cyril Ramaphosa announced on 10 June, that the licence-exemption cap on self- or distributed-generation plants would be raised from 1MW to 100MW. The increase in the threshold will enable mining companies and other entities to build power generation units of up to 100MW without applying for a licence through the National Energy Regulator of South Africa (Nersa). This action was introduced to help address the country’s electricity crisis,which has been weighing down economic growth and confidence for more than a decade. This move was welcomed by the industry.

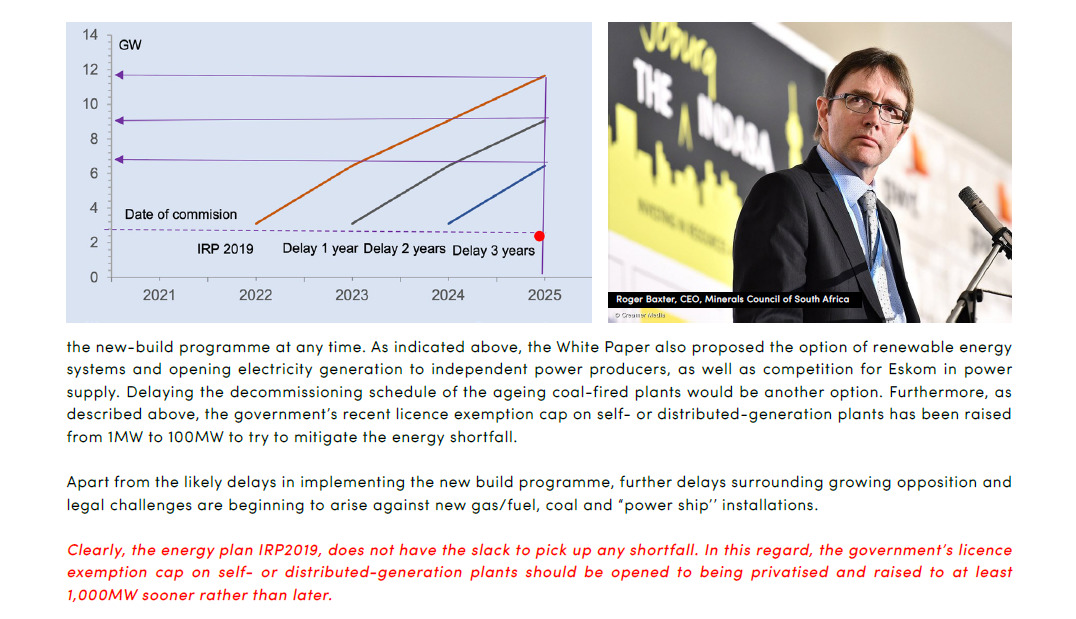

In this conversation thus far, I have alluded to the pivotal key factors which must be met in order to neutralise the energy gap. Unfortunately, Eskom and the government do not have a good track record in meeting project deadlines. Therefore, the energy gap is likely to widen instead of being neutralised.

The objective of this review is to provide evidence and timing to support the scenario that the two pivotal key factors will or will not be achieved in a timely manner. The outcome will determine the degree and level of load shedding and the impact on PGM supply from South Africa.

In this regard, I have also alluded to the track records of the government and Eskom concerning the delivery of power to South Africa. The country has already experienced 14 years (from 2007) of intermittent load shedding at stages between 2 and 6. The higher the load shedding stage the more frequent load shedding becomes.

The subject matter concerning Eskom and its future is not new. The impact of a diminishing and intermittent electricity supply is the result of a number of downgrading factors, which are attributed to a “cauldron” of political ideology, political interference, state capture, mismanagement, lack of skills, poor maintenance, nscheduled breakdowns, crime and corruption.

It should be noted that Eskom has an ageing fleet of coal-fired power stations. Historically, the EAF of these power stations was above 80% (2000). Over the past ecade, the EAF has declined to around 67% and lower, which has further constrained power supply resulting in load shedding.

Eskom is currently struggling to meet electricity demand and has already started load shedding. Notwithstanding, Eskom is scheduled to remove around 3.5GW from the national grid by decommissioning five coal-fired stations, which will have reached the end of their 50-year lifespan between 2021 and 2025. Eskom estimates that without additional capacity, there will be an electricity supply shortfall of around 5GW over the next four years (2025).

Plans to install alternative renewable energy to neutralise and bolster the diminishing electrical supply “slipped” mainly because of a failure to implement policy between 2015 and 2018, which led to a breakdown in procurement. It has taken, in all, around two years, until April 2021, of effectively doing nothing about the looming energy crisis. The government has hastily restarted utility scale procurement processes for renewables according to the government’s upgraded IRP2019,

which sets out the transition from the existing dependence on fossil fuels to a mix of renewable electricity energy sources to replace this widening energy gap. The IRP2019 also calls for the restructuring of Eskom into Eskom Holdings with three new subsidiaries: Generation, Transmission and Distribution to improve the effectiveness of Eskom.

The key question in this regard:

Will the planned transition of the ageing coal-fired plants to a mix of renewable electricity energy sources be timeously implemented? Or will there be continuous bouts of project “slippage” with Eskom having to continuously play “catch up”, thereby having to implement higher stages of load shedding.

To cap it all, Eskom is not generating enough cash to fund its operations and service its R401bn (US$27bn) debt (Eskom annual report 2021). So where will the money come from? Among others, a significant increase in tariffs is expected to fund, in part, the new build programme.

As indicated, the subject matter concerning Eskom and its future is not new. A number of well-known leading engineering and energy experts, CEOs of large industrial and mining organisations, the Minerals Council South Africa, the CSIR, South African Independent Power Producers Association (SAIPPA) and many other associated organisations have been raising “alarm bells” surrounding the progressive demise of Eskom since 1994.

Currently, these “alarm bells” are at full volume!

THE ROOTS OF ESKOM’S DEMISE

The objective of this section is to “set the scene” surrounding the major factors that have led to the decline in Eskom’s electricity supply.

The roots of Eskom’s decline date back to 1994, some 27 years ago, when the ANC government took power. The demise of Eskom has been attributed to numerous “crippling factors”, which have been well documented and reported on. As indicated, much of these downgrading factors are attributed to political ideology, political interference and meddling, state capture, mismanagement, lack of skills, poor maintenance, unscheduled breakdowns, crime and corruption. In a paper published in @ Liberty2015, the policy bulletin of the IRR, engineer and energy expert, Andrew Kenny said “that from a well-run state organ, Eskom’s politically appointed new managers appear to have little interest in

ensuring future electricity supply.

‘’Accountants replaced engineers at senior levels, and those accountants lost sight of Eskom’s fundamental purpose, which is simply to provide electricity and cover its costs, not make a big profit or a high rate of return”.

Experts also blame Eskom for not building more power stations. Many of Eskom’s coal-fired plants are old and reaching their end of life. It is noted that 60%, or 22.5GW, of Eskom’s nominal capacity of 37.4GW is generated by plants that are between 35 and 59 years old.

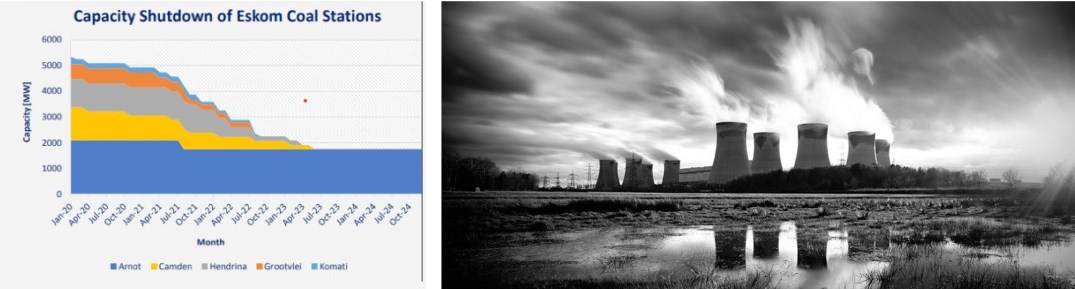

Five of Eskom’s coal-fired power stations are expected to be decommissioned by 2025: Komati, Camden, Grootvlei, Hendrina and Arnot, which are now 59, 54, 52, 51 and 50 years old respectively. It is noted that among others, the EAF from the coalfired fleet has declined from over 80% in 2000 to around 67% over the past decade, which has contributed to a continuous decline in power supply resulting in load shedding.

The relationship between the EAF and power supply will be discussed further in the load shedding section of this review.

The graphic (CSIR) on the left illustrates the scheduled decommissioning of the ageing coal-fired plants. It is important to note that the shutdown of the ageing coal-fired plants declines steeply from 2022 through to 2050, which amounts to a coal-fired energy gap of around 30GW.

Eskom expects decommissioning of approximately 24.1GW of coal-fired power plants in the period beyond 2030 to 2050.As indicated, the government’s IRP2019 sets out the transition from the existing dependence on fossil fuels to a mix of renewable energy sources to fill this energy gap.

Eskom indicates that despite decommissioning of old power plants and preference for renewables and gas, coal remains dominant in the energy mix for the planning period up to 2030.

It should be noted that Eskom does not have a good track record with regards to EAF, caused mainly by mismanagement, cost constraints, the lack of skills and unscheduled breakdowns of the ageing coal-fired plants. In this regard, the projected rate of decline of its coal-fired plants may well be “optimistic”.

The steep decline in the scheduled shutdown of ageing coal-fired plants after 2022 through to 2050 illustrates just how precarious South Africa’s energy crisis is, affecting in particular South Africa’s PGM supply.

On this subject, Ted Blom noted that Eskom was facing what the Fossil Fuel Foundation called a ‘coal cliff’.

Clearly, the degree of slippage surrounding new capacity will progressively impact PGM supply. In this regard, Eskom and the government do not have a good track record of completing projects on time.

For example, two mega coal-fired plants with an output of 4.8GW each were commissioned to be built in 2007. Eskom said at that time Medupi and Kusile will be completed by 2015 and will play an important role in solving South Africa’s energy challenges. The construction of these plants was plagued by a multitude of delays,

spiralling costs and corruption scandals.

Current forecasts indicate that Medupi’s completion date has been extended to 2021,with Kusile expected to be completed in 2025. It is noted that Medupi and Kusile have been de-rated at below name-plate rating, meaning that these plants are unable to provide the full complement of energy for their rating. It should be noted that this energy shortage occurs despite the already-committed capacity from renewable energy projects and the commissioning of the remaining units at Medupi and Kusile.

It is interesting to note that the government published a White Paper on energy policy in 1998, which was full of sensible suggestions, according to energy experts. This White Paper proposed restructuring Eskom’s generation, distribution and transmission operations,which has finally been adopted in IRP2019, some 22 years later. The White Paper also proposed the option of renewable energy systems and opening electricity generation to independent power producers, as well as competition for Eskom in power supply. Politically, the notion of privatisation did not sit well with the ANC’s Marxist doctrine. In this regard, the government banned Eskom from building new power stations. It should be pointed out that in 1998 Eskom had surplus capacity but expected demand to outstrip supply in 2007 if nothing was done to replace its ageing coal-fired power stations.

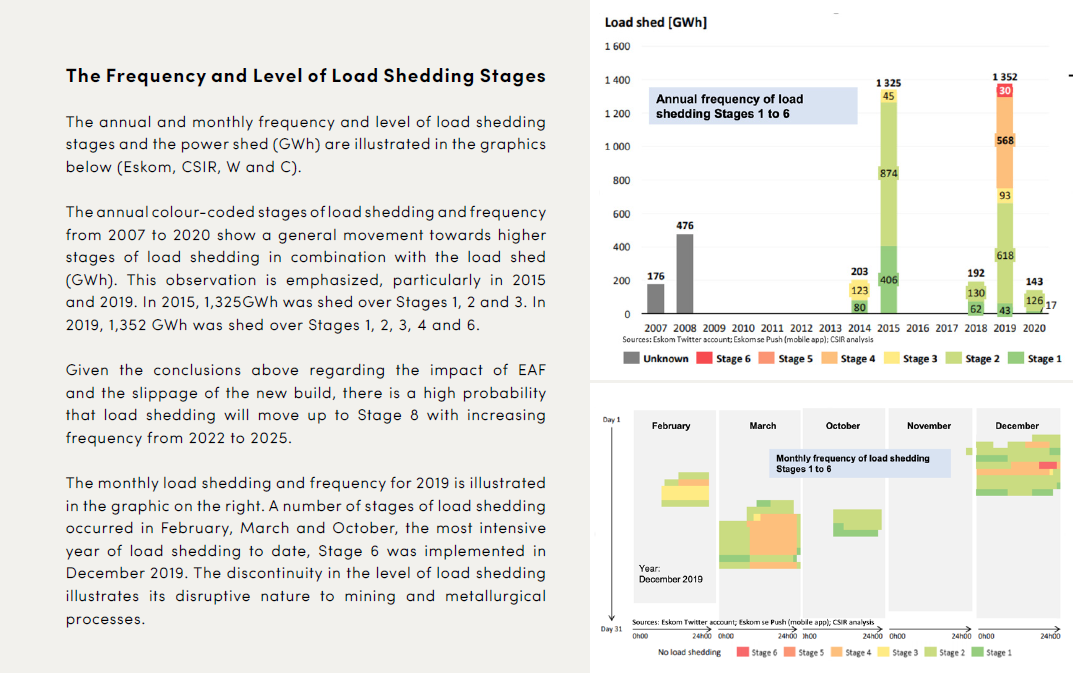

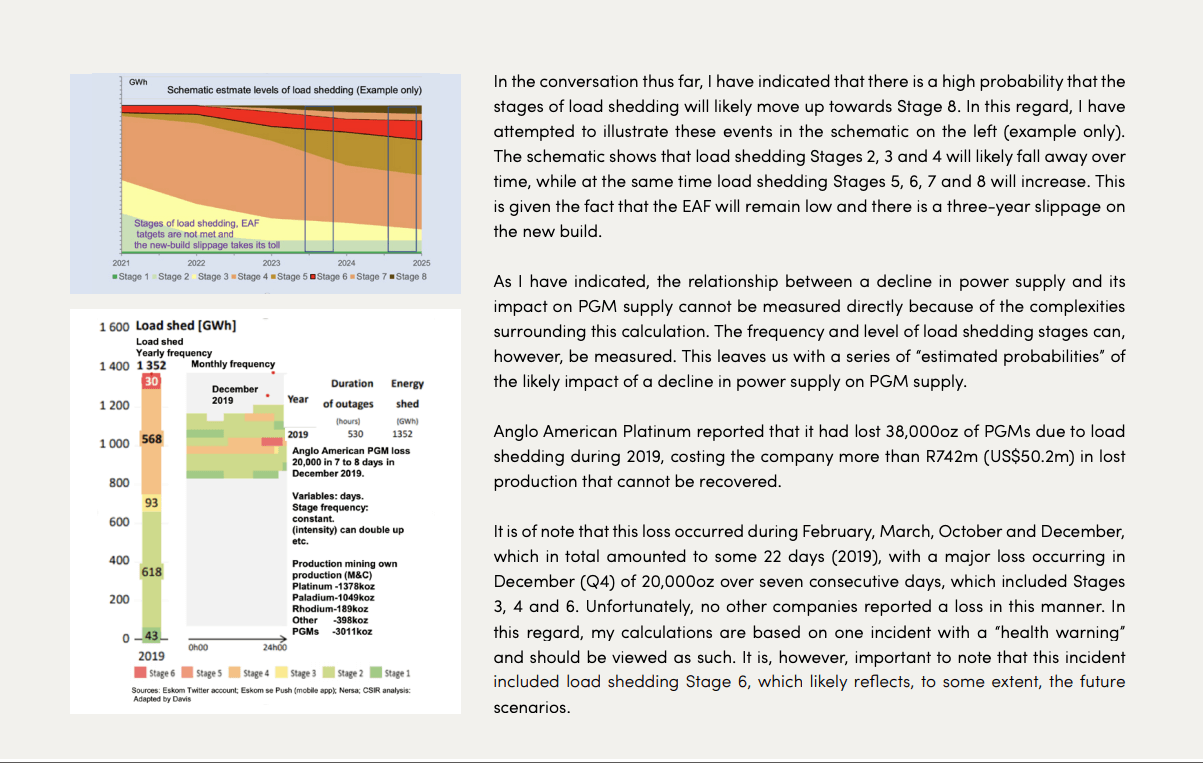

The graphic on the right illustrates the load shedding events since 2007 together with energy shed and the estimated economic impact. Presentation CSIR, J Wright, and J Calitz, January 2020 (abbreviated to CSIR, W and C).

It is important to note that it is assumed that load shedding takes place for the full hours in which it was implemented. Practically, however, load shedding and the stage may occasionally change during a particular hour. The graphic also illustrates how complex it is to forecast load shedding. For example, in 2019, load shedding Stages 2, 3, 4, 5 and 6 were implemented,with most load shedding falling in Stages 2 and 4. It stands to reason that the longer load shedding remains at higher stages (4 to 8) and at higher frequencies, the greater the impact on PGM mine supply. It should be noted that the mining companies’ load shedding protocols are somewhat different from the national protocol. The definition of stages of load shedding does not change.

Energy expert Ted Blom has indicated (MyBroadband) that he would not be surprised if between now and the end of winter we experience

Stage 6 load shedding, and even Stage 8 or above, which is a possibility. Ted Blom also indicated that based on Eskom’s own forecasts, 2021 is going to be the worst year of load shedding on record. The relationship between the load shedding stage and the impact on PGM

supply is discussed later in this review.

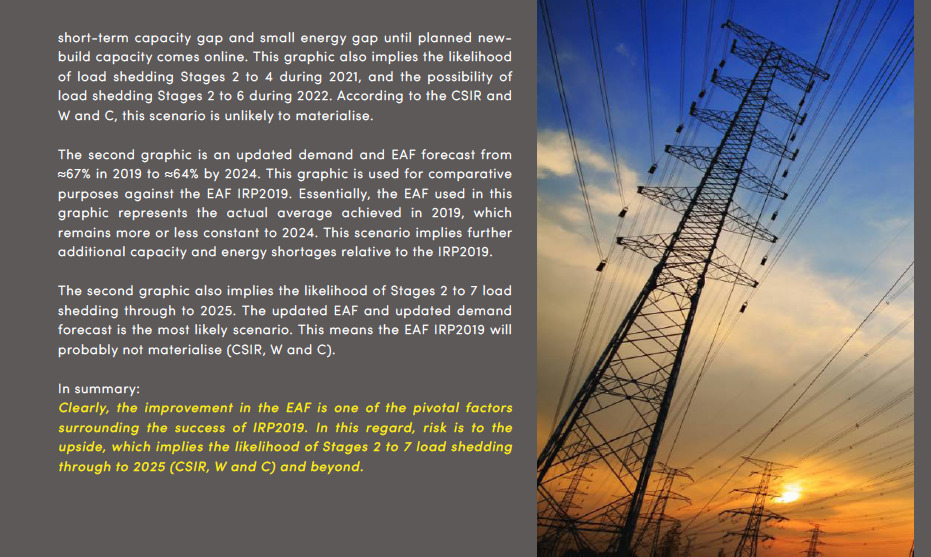

COAL GENERATION COMPARISON AT A GLANCE

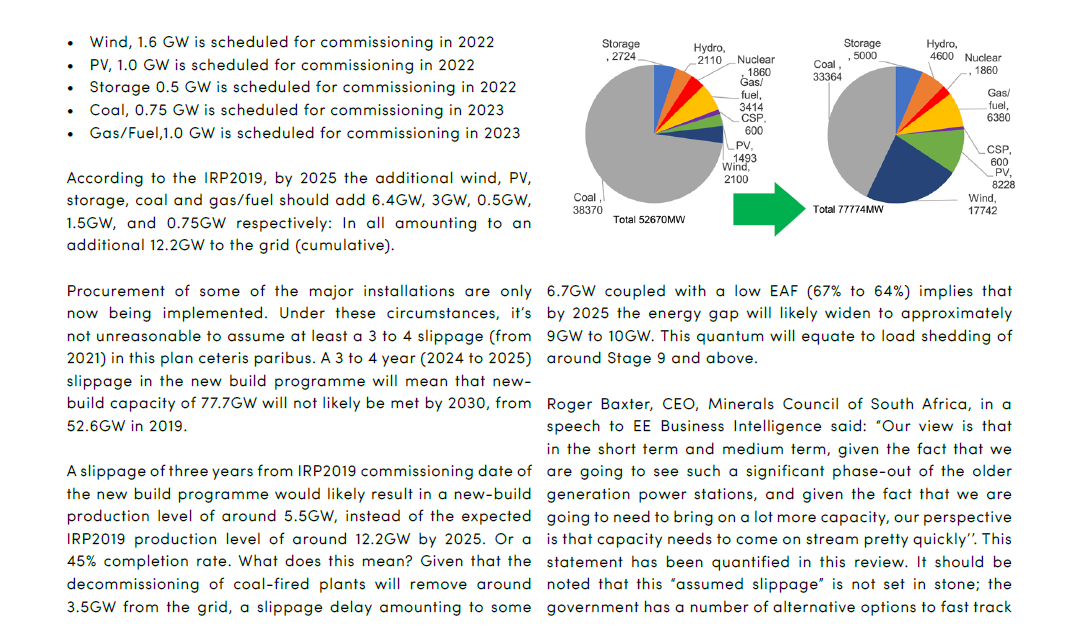

Thus far, this study has focused on the complexity of forecasting load shedding and the impact of EAF on load shedding. This section of the conversation uses Eskom’s data to illustrate the ballooning energy gap if the new-build capacity does not come online as planned.

The graphic on the left, illustrates a diminishing electricity supply as Eskom’s ageing coal-fired plants are decommissioned through to 2030. The graphic also illustrates, for comparative purposes, the equivalent coal-fired capacity transition development plan (TDP) for 2019 and 2020, required between 2020 and 2030 to neutralise the expanding energy gap, which reaches a deficit of around -9.1GW, if not replaced.

(Eskom TDP 20 October 2021 to 2030). As indicated, Eskom has recently warned that it expects load shedding (Stage 4) to increase towards the end of 2021, as it is facing shortfalls that are expected to continue for at least another five years.

The graphic, however, implies that the energy gap is ballooning and will likely advance much more rapidly through load shedding stages of around 2 to 9 between 2022 and 2025 if additional capacity is not implemented timeously. The acceleration of the energy gap shortfall has been attributed in part to a failure to implement policy between 2015 and 2018, which led to a breakdown in procurement until April 2021.

This graphic confirms the urgency of the implementation of the TDP from the existing dependence on fossil fuels to a mix of renewable electricity energy sources to neutralise this energy gap if not expedited rapidly. The graphic also implies that the TDP upgrade is of vital importance and should go hand-in-hand with the alternative renewable energy and gas-coal installations.

It is important and disturbing to note that according to Eskom’s graphic, should there be any further slippage in the installation of renewable energy sources and the completion of the transition development plan (TDP) the supply gap will balloon to -9.1GW by 2030. This, according to Eskom, represents 10 stages of load shedding! This level would be disastrous for South Africa and the mining industry.

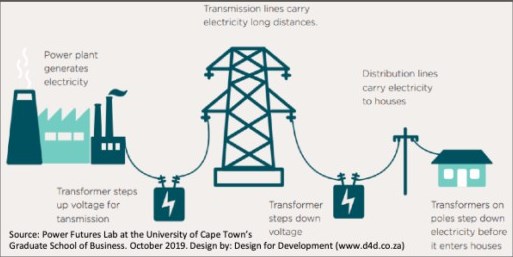

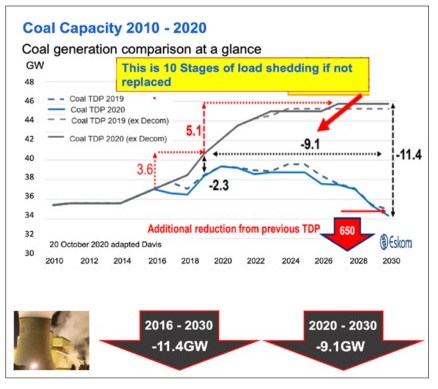

Eskom has numerous sub-stations and transformers, with approximately 33,000km of transmission lines and has a national footprint in South Africa. Eskom indicates

that the overall transmission network performance, has deteriorated over the past 5 years, and requires capital for replacement.

Eskom has a 10-year transmission refurbishment plan in place based on asset condition assessments, asset criticality and network risks. (See graphics on the right).

Quote from Eskom’s TDP 2021 to 2030 presentation 29 October 2019:

“Existing generation fleet replacement with both new energy (wind and solar) and new capacity (back up gas, batteries, etc.) is required irrespective of load growth. Transmission expansions are critical to create access for these new energy sources and capacity location. Load growth plays a significantly lower role but is still important.”

ESKOM SUPPLY TO THE PGM MINING INDUSTRY

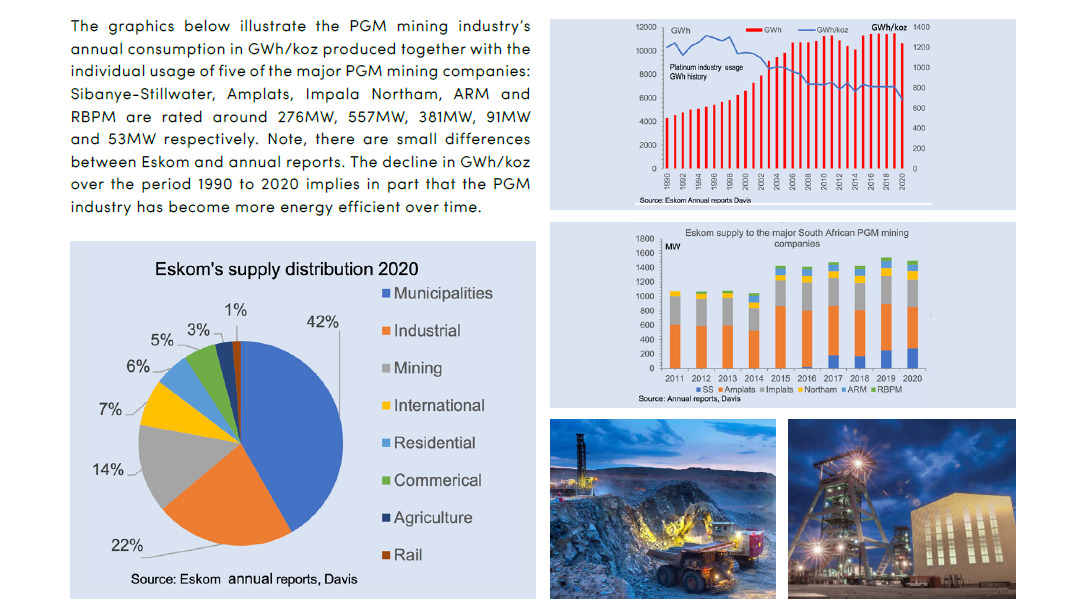

Eskom supplies some 14% of its total supply to the mining industry (3,284MW) of which around 40% (1,314MW) is to the platinum mining industry (Eskom annual report 2020).

REDUCING THE IMPACT OF LOAD SHEDDING IN THE PGM INDUSTRY

As indicated in the introduction, on 10 June, 2021 South Africa’s President Cyril Ramaphosa announced that the licence-exemption cap on self- or distributed-generation plants would be raised from 1MW to 100MW. The increase in the threshold will enable mining companies and other entities to build power generation units of up to 100MW without applying for a licence through the National Energy Regulator of South Africa (Nersa). This move was welcomed by the mining industry.

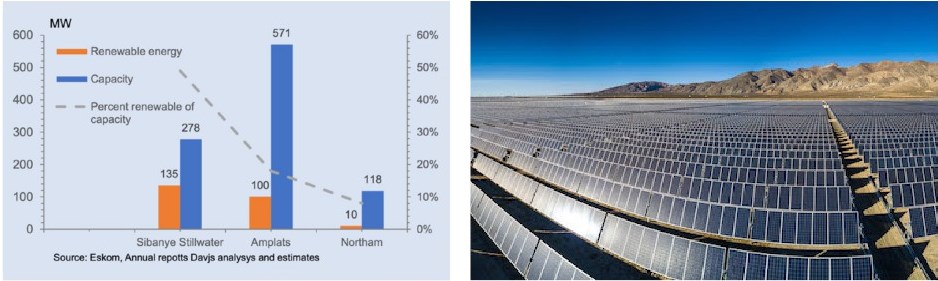

In this regard, Sibanye-Stillwater is preparing feasibility studies for prospective 50MW and 85MW solar PV projects for its Rustenburg and Marikana operations respectively. Anglo American Platinum is looking at building a 75MW to 100MW solar PV plant to support its Mogalakwena mine and concentrator, while Northam Platinum will likely install modules of 10MW. Notwithstanding, the move to privatising supply will likely encounter regulatory bumps along the way.

The graphic above illustrates the capacity in MW attributed to Sibanye-Stillwater, Anglo American Platinum and Northam compared to the allowance of 100MW. It is important to note that the exemption is applied not only to the company, but also to the entities and projects within the company for example, Sibanye-Stillwater can install 50MW and 85MW solar PV projects at its Rustenburg and Marikana operations respectively. Similarly, Anglo American Platinum, apart from Mogalakwena mine, the company can install a solar PV plant at its Amandelbult mine etc.

According to Gold Fields CEO Chris Griffith, the solar PV plant it is currently building will generate more than 20% of the mines’ electricity and will save Gold Fields R120m (US$8.1m) a year in power costs. The introduction of solar PV energy will reduce operating costs, which currently make up about 13% of Gold Fields’ operating costs.

The introduction of a renewable energy source brings an additional advantage as this will reduce the carbon footprint of the mines, thereby reducing carbon tax payments.

Important Notice

General Disclosures, Disclaimers and Warnings

This Report (“the report”) in respect of the global PGM Industry is directed at and is being issued on a strictly private and confidential basis to, and only

to, Professional Clients and Eligible Counterparties (“Relevant Persons”) as defined under the Investment Research Regulatory Rules and is not directed at Retail Clients. This report must not be acted on or relied on by persons who are not Relevant Persons. Any investment or investment activity to which this Report relates is available only to Relevant Persons and will be engaged in only with Relevant Persons.

The Report does not constitute or form part of any invitation or offer for sale or subscription or any solicitation for any offer to buy or subscribe for any securities in any Company discussed nor shall it or any part of it form the basis of or be relied upon in connection with any contract or commitment whatsoever.

The opinions, estimates (and where included) projections, forecasts and expectations in this report are entirely those of Dr David Davis as at the time of the publication of this report, and are given as part of his normal research activity, and should not be relied upon as having been authorised or approved by any other person, and are subject to change without notice.

There can be no assurance that future results or events will be consistent with such opinions, estimates (where included) projections, forecasts and expectations. No reliance may be placed for any purpose whatsoever on the information or opinions contained in this Report or on its completeness and no liability whatsoever is accepted for any loss howsoever arising from any use of this Report or its contents or otherwise in connection therewith. Accordingly, neither Dr David Davis nor any person connected to him, nor any of his respective Consultants make any representations or warranty in respect of the contents of the Report. Prospective investors are encouraged to obtain separate and independent verification of information and opinions contained in the Report as part of their own due diligence. The value of

securities and the income from them may fluctuate. It should be remembered that past performance is not necessarily a guide to future performance.

Dr David Davis has produced this report independently of the companies that may be named in this report except for verification of factual elements. Any opinions, forecasts, projections, or estimates or other forward-looking information or any expectations in this Report constitute the independent judgement or view of Dr David Davis who has produced this report (independent of any company discussed or mentioned in the Report or any member of its group).

The Report is being supplied to you for your own information and may not be reproduced, further distributed to any other person or published, in whole or in part, for any purpose whatsoever, including (but not limited to) the press and the media. The distribution of the Report in certain jurisdictions may be restricted by law and therefore any person into whose possession it comes should inform themselves about and observe any such restriction.

The Report has been prepared with all reasonable care and is not knowingly misleading in whole or in part. The information herein is obtained from sources that Dr David Davis considers to be reliable but its accuracy and completeness cannot be guaranteed.

Dr David Davis Certification

Dr David Davis attests that the views expressed in this report accurately reflect his personal views about the global Platinum Industry. Dr David Davis does not hold any interest or trading positions in any of the Companies mentioned in the report.